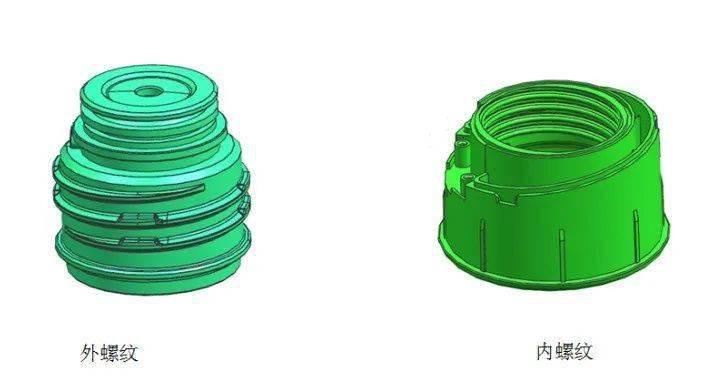

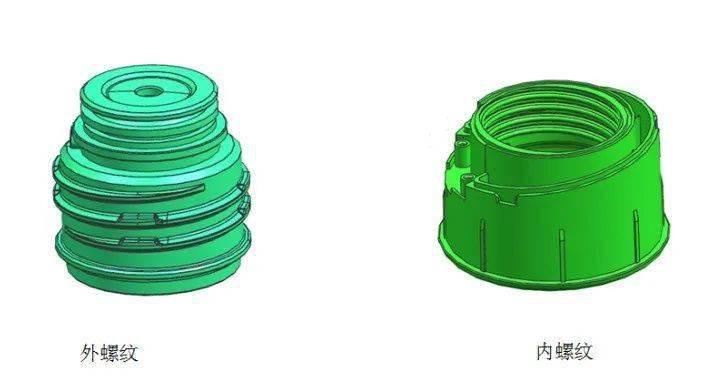

In our plastic mold design industry, there are many types of mold structures. For general mold designers, ordinary sliders and inclined roof structures are familiar to everyone, and they can be designed. But for some special and typical molds There will always be a feeling that there is no way to start with the structure. Today I will explain to you the key points of the design of the screw thread mold structure. I hope that the majority of university mold design enthusiasts and partners who want to know more about the screw thread heart pumping structure will be inspired: Plastic products Threads are divided into two types: external threads and internal threads. For external threads with low precision, Huff blocks are generally used to form them, while internal threads mostly need thread unloading devices. Here is a brief introduction to the demoulding method of internal threads and the introduction of gears:

1. According to the action mode:

①The threaded core rotates, and the push plate pushes the product to disengage;

②The threaded core rotates and retreats simultaneously, and the product naturally disengages.

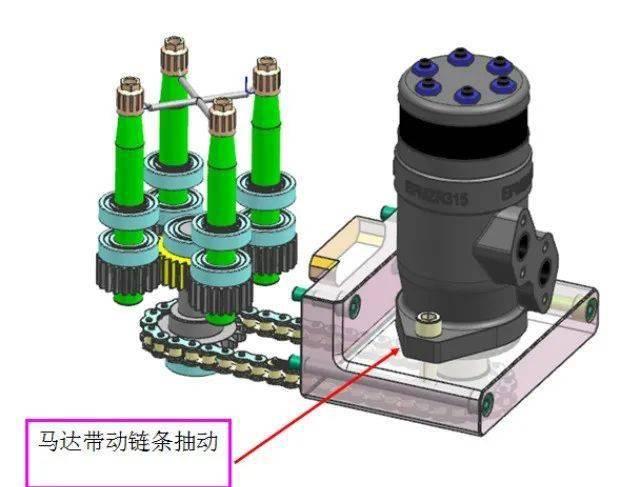

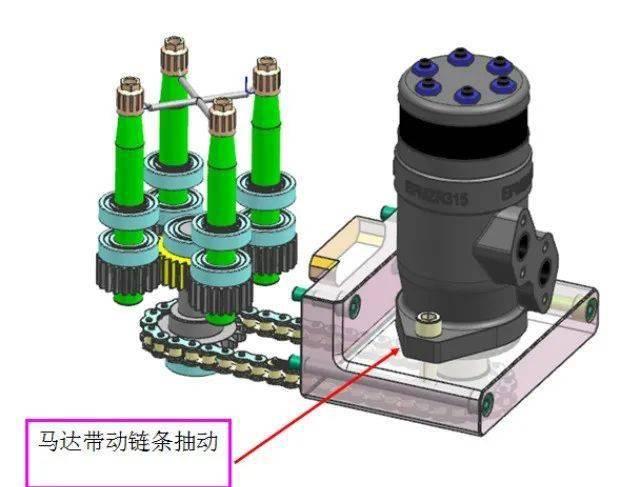

2. According to the driving mode: the types of tooth extraction molds are generally divided into two types: one is the rack driven by the oil cylinder, and the other is the chain driven by the motor. The following picture shows the rack driven by the oil cylinder: The picture below shows the motor driven Chain twitching:

3. The twitching principle of the screw mold: the tooth pitch of the braces and the braces must be the same as the tooth pitch of the product, and the braces play a guiding role.The oil cylinder drives the rack 1 to move—the rack 1 drives the gears 2 and 3 to rotate—the gear 3 drives the gear 4 to rotate—the gear 4 and the screw are positioned as one and rotate together, as shown in the figure below:

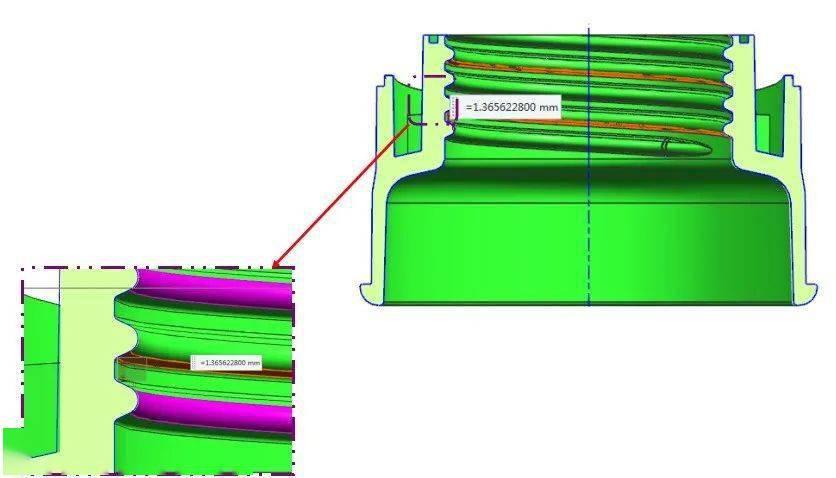

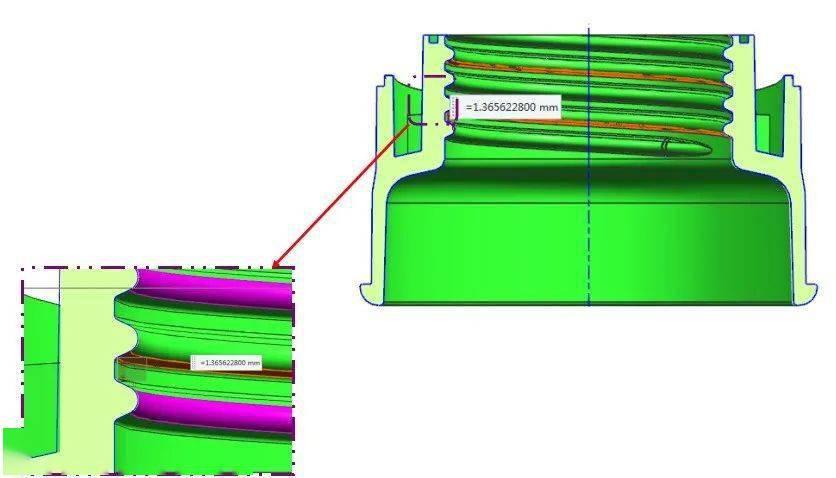

4. When designing the screw tooth mold It is necessary to know the tooth pitch at the time, the definition of the thread pitch is the vertical movement distance of the screw tooth in one revolution, as shown in the figure below:

5. The pitch of the product glue and the thread pitch of the screw must be the same, otherwise the product will be easily scratched.

6. How to call gears and racks: Hu Bo plug-in can call gears and racks. According to the product ranking in our mold, we can determine the index circle required by our gears directly, and then the gear modules are the same.Then the gear can be called out as shown in the figure below:

7. The calling method of the rack: the rule of calling with Hu Bo’s external rack is also to follow the formula (modulus X number of teeth = diameter of the pitch circle)

8. Want to design a screw tooth mold , you must understand the relationship between the rack and the gear. The following figure shows the relationship between the rack and the gear and the relationship between each gear:

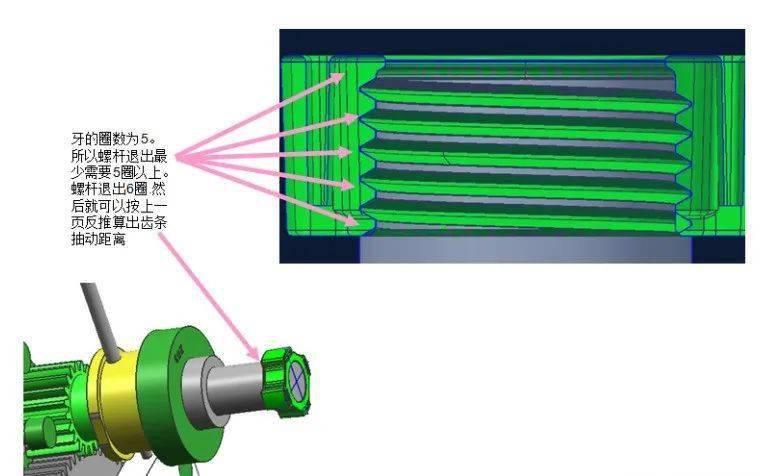

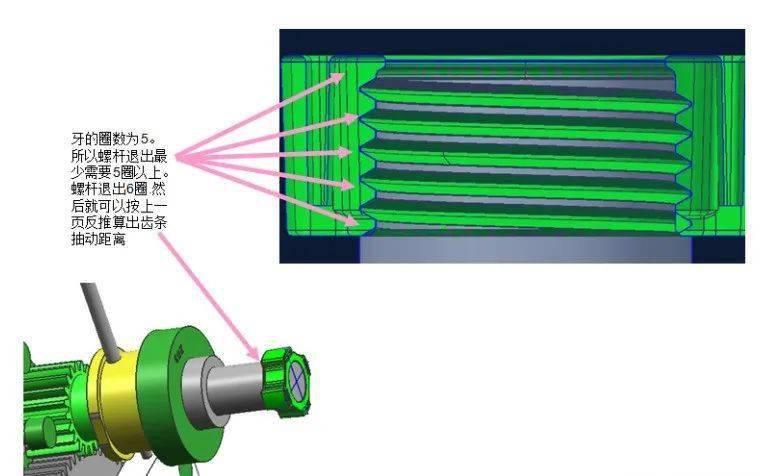

9. Calculation of the number of exit turns required by the product and the length of the rack: the number of turns of the teeth is 5 , then the screw needs at least 5 turns to exit.The screw exits for 6 turns. Then you can reversely calculate the rack twitching distance according to the previous page:

Fine Group was established in 1968 and is headquartered in Hong Kong.Since the establishment of production bases in mainland China in 1988, it has built large factories in Shenzhen, Nansha, Guangdong, and Suzhou; a powerful group company with offices in Chicago, USA, and offices in Beijing, Shanghai, Tianjin and other places.The group now has more than 4,000 people.Exquisite mainly produces plastic electroplating products, such as: massage showers, plumbing equipment, plastic injection molding, auto parts electroplating and so on.PVD coating.Professional PVD Nano Tools Titanium Coating AlTiN (Aluminum Titanium Nitride) Coating TIN (Titanium Nitride) Coating DLC (Diamond Like Carbon) Coating ALCRN (Aluminum Chromium Nitride) Coating CrN (Chromium Nitride) Coating TiCN (Titanium Nitride Carbide) coating quality is the leading plastic electroplating manufacturer in Asia.AlTiN (aluminum titanium nitride) coating Titanium aluminum nitride coating is a coating developed on the basis of aluminum titanium nitride.The content of aluminum (TiAlN) in the coating is further improved, so the oxidation resistance of the coating is further improved, and the maximum heat resistance temperature... TIN (titanium nitride) coating TiN is a general-purpose PVD Coatings with high cost performance are fairly stable compounds that can increase tool/tool hardness and have a high oxidation temperature.The coating is used for high-speed steel cutting tools or forming... DLC (diamond-like carbon) coating DLC coating is also called diamond-like carbon coating, which has both high hardness (>HV1500) and low dry friction coefficient (0.05 -0.1 ), is a coating that can achieve oil-free self-lubrication.This coating has very low coating...ALCRN (Aluminum Chromium Nitride) coating AlCrN coating is widely used, especially suitable for stamping dies, stretch forming dies...etc, with good toughness , abrasion resistance and abrasion resistance.The combination of these properties makes it ideal for light to moderate forming applications... CrN (Chromium Nitride) Coating The higher surface hardness, lower coefficient of friction and lower residual stress of CrN coating make it For wear resistance, metal-to-metal friction applications.Moreover, the chromium nitride coating has high toughness and is resistant to water... , good lubricity, high hardness (HV3200), wear resistance and other characteristics.Suitable for lower friction coefficients【Shenda Kaituo Mould Products Co., Ltd. is the mold manufacturing supplier of Jingxing Group】 Jingxing Group insists on providing customers with high-quality products and excellent services, and has established itself among customers through more than 40 years of efforts With a good reputation, customers include many world-renowned enterprises, and the products are exported to Europe, America and Japan.Shenzhen Shenda Kaituo Mould Products Co., Ltd. was established on October 1, 2005. It has been committed to various auto parts molds, plastic molds, screw molds, gear molds, fan blade molds, die-casting molds, two-color molds, stacking molds and The development, design and manufacture of IMD molds aim to build a first-class mold factory.At present, auto parts molds such as car audio molds, car digital TV molds, car lamp molds, etc. currently absorbed by the factory; plastic molds and die-casting products include digital communication molds such as mobile phone shell molds, PDA molds, GPS molds, telephone molds, Bluetooth headset molds, etc.; computer accessories molds such as mouse molds, liquid crystal display molds, speaker molds, etc.; testing instrument molds such as fingerprint instrument molds, bank terminal molds, card reader molds, etc.; network equipment mold products such as router molds, switches Molds, converter mold products, etc.At present, the company has complete mold manufacturing equipment and manufacturing system, and always insists on recruiting high-quality and high-level professional and technical personnel to make suggestions and contribute to the company's long-term development.The company implements the corporate philosophy of "integrity, quality, reasonable price and sustainable development", regards product quality as the foundation of survival and development, persists in leading with technological innovation, and promotes the efficient and high-quality development of the company with the cohesion of team elites!After years of development, there are now 38 people.3 The testing equipment includes one Sirui 3D and two 2.5D.6 sets of CNC computer gongs, 6 sets of fast wire feeders, 2 sets of Japanese Sodick slow wire feeders, 10 sets of CNC EDM spark machines, 6 sets of ordinary gong machines, 8 sets of imported grinding machines, and 9 sets of injection molding machines ranging from 100 to 250 tons.The main molds are automobile molds, electronic and electrical molds, two-color three-color molds, and laminated molds.The size ranges from 0.5MM spare parts to 17 tons of complete large molds.

Kennethchui

Mobile: 13715334662

E-mail: everwinmold@163.com

QQ: 2819840570

Website: https://shunqiang.diytrade.com

Website: https://everwinmold.diytrade.com